Rupes LTA 125 Triple Action Polisher | 5" Pneumatic Random Orbital

RUPES Polishers

$565.00

MSRP:

$708.00

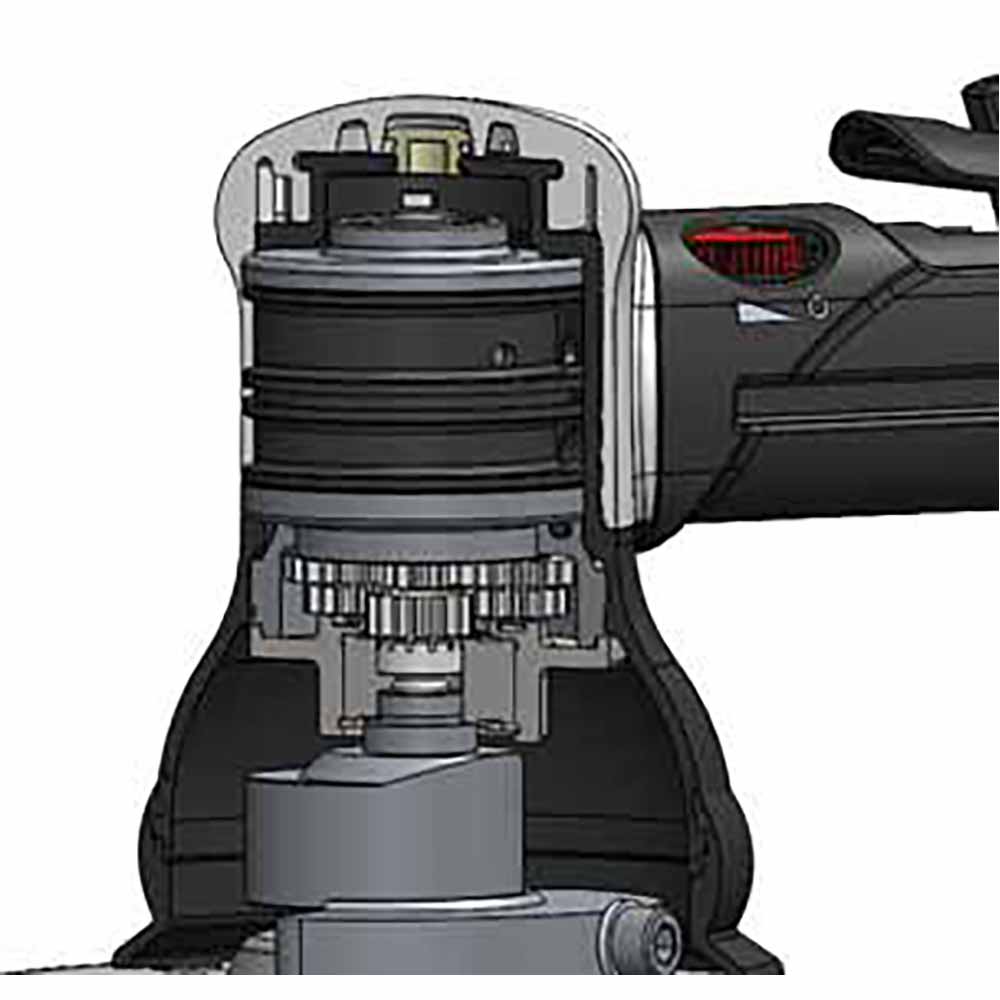

Rupes LTA 125 Triple Action Polisher | 5" Pneumatic Random Orbital

Ships FREE

*This is a pneumatic tool, please review air consumption and make sure you have the appropriate air compressor before...

RUPES LHR75 Pneumatic Mini Polisher | Random Orbital 3”

RUPES Polishers

$325.00

MSRP:

RUPES LHR75 Pneumatic Mini Polisher | Random Orbital 3”

This small pneumatic random orbital polisher has a 15mm orbit and a 75mm (3 inch) backing pad, allowing the tool to work in awkward and...

Rupes LHR75E Mini Random Orbital Polisher | Bigfoot 3" Backing Plate

RUPES Polishers

$315.00

MSRP:

Rupes LHR75E Mini Random Orbital Polisher | Bigfoot 3" Backing Plate

12mm Orbit - 3" Backing Plate

Ergonomically Perfect With its non-slip rubber inserts on the front cover, the LHR 75

RUPES Skorpio III Palm Sander Kit | Pneumatic Random Orbital 6mm

TCG Polisher Kits

$209.00

MSRP:

RUPES Skorpio III Palm Sander Kit Includes:

Skorpio III 6mm (without vacuum)

6" Backing Plate

2x 1500 Foam Cut Discs

2x 2000 Foam Cut Discs

2x 3000 Foam Cut Discs

RUPES Skorpio III Sander 6mm | Pneumatic Random Orbital Palm Sander | No Vac

RUPES Polishers

$189.00

MSRP:

RUPES Skorpio III Sander 6mm | Pneumatic Random Orbital Palm Sander

6" Backing Plate 981.500 Included6mm orbit for balanced all-around performance

No Vacuum